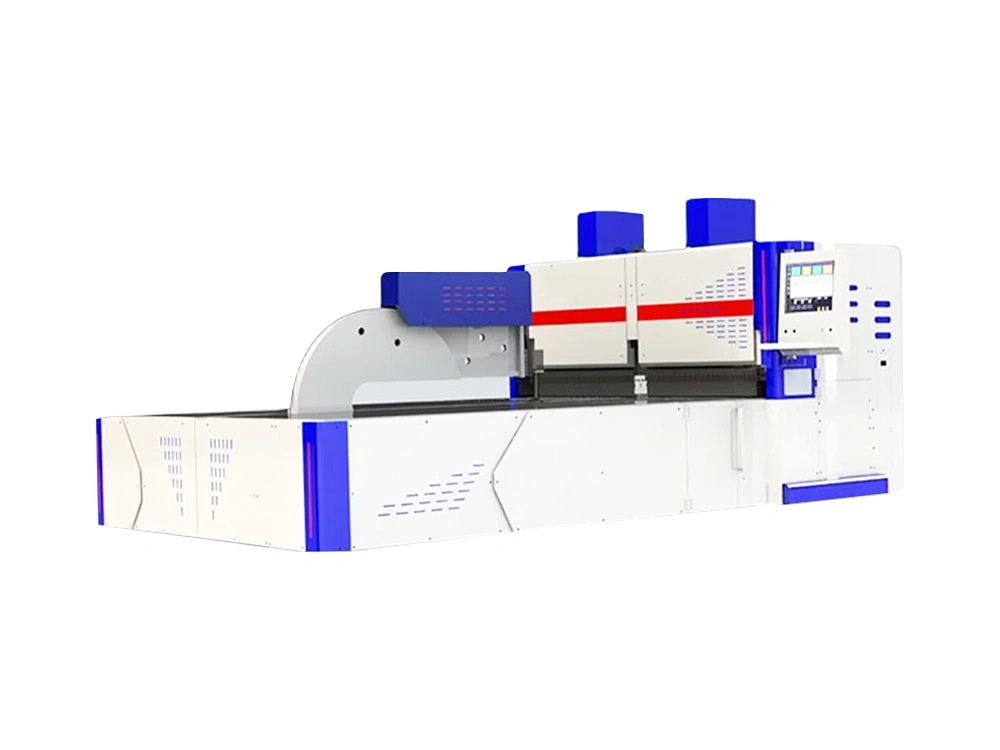

Intelligent flexible bending center principle

The principle of the intelligent flexible bending center is to use an intelligent system composed of sensors and controllers to sense and control the height information and angle direction on the bending machine, thereby achieving intelligent control of the bending process. Specifically, the intelligent flexible bending center uses servo-electric technology and a high-precision angle correction database, which can automatically create multiple bends for each side, including up/down bends, flat or curved bends, etc. At the same time, a high-precision temperature-controlled furnace is used for the fuselage, and the tempering heat treatment process is carried out according to the temperature curve corresponding to the material, and then a full-frequency vibration aging treatment is performed for a sufficient period of time to release internal stress, ensure long-term stability in use, and ensure the overall accuracy of the system. Stability. In addition, the intelligent flexible bending center also has the characteristics of an intelligent lubrication system and high mechanical operation synergy, which can successfully complete the combination of various complex actions, and the overall machine work efficiency is very high. The daily maintenance workload is very low. It has a self-lubricating system for the whole machine. When the oil level is lower than the value, the system will automatically alarm. You only need to add lubricating grease according to the program prompts.

To sum up, the intelligent flexible bending center achieves automated, high-precision, flexible and reliable bending processing of metal sheets by using advanced sensors, controllers and servo technologies, improving production efficiency and Reduce costs and improve product quality and competitiveness.

The intelligent flexible bending center is a kind of equipment specially designed for bending metal sheets. It has the following characteristics:

High degree of automation: The intelligent flexible bending center can realize automatic positioning, clamping and bending of plates. The entire bending process does not require manual intervention, improving production efficiency.

High precision: The intelligent flexible bending center uses high-precision servo motors and control systems to achieve precise bending angles and dimensions, ensuring product accuracy and quality.

Good flexibility: The intelligent flexible bending center can adapt to plates of different specifications and shapes, and can quickly adjust bending parameters and molds to facilitate the production of multiple varieties and small batches.

High reliability: The intelligent flexible bending center adopts good components and good structural design, has high stability and reliability, and reduces the failure rate and maintenance costs.

Strong scalability: The intelligent flexible bending center can be integrated with other automation equipment to realize the automation of plate conveying, loading and unloading, welding, spraying and other processes, making it convenient for enterprises to upgrade and transform their production lines.

In short, the intelligent flexible bending center is an efficient, high-precision, high-flexibility and high-reliability metal sheet bending processing equipment. It is suitable for enterprises and production lines of all sizes and can improve production efficiency, reduce costs and improve product quality. and competitiveness.