Fully automatic sheet metal flexible processing line, which organically combines nowadays the traditional three major parts (shearing, punching and folding) plus laser cutting into one, and fully automates all the processes from feeding, transferring, stacking and unloading of metal materials, which fully ensures the high quality, high efficiency and saves human resources in sheet metal processing.

Fully automatic sheet metal flexible processing line, which organically combines nowadays the traditional three major parts (shearing, punching and folding) plus laser cutting into one, and fully automates all the processes from feeding, transferring, stacking and unloading of metal materials, which fully ensures the high quality, high efficiency and saves human resources in sheet metal processing.

Flexible bending centre focuses on solving all kinds of complex sheet metal and bending problems in metal forming. Through the multi-axis concurrent linkage, automatically complete the sheet metal work, from a technical point of view to solve the dependence on moulds and manpower, effectively improve production efficiency and reduce production costs.

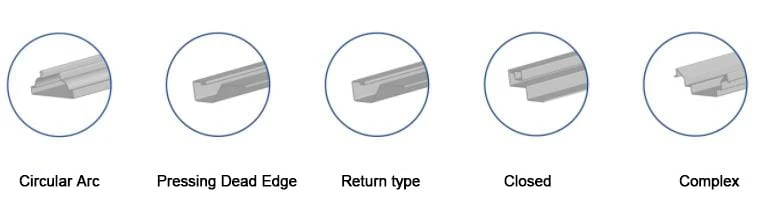

It is easy to realise sheet metal bending needs of arc, dead edge, return type, closed type and other complex types.

Flexible bending centre can be widely used in the field of steel cabinet shells (filing cabinets, tool cabinets, outer shrouds, electrical cabinets, communication cabinets, gas cabinets, water meter cabinets ......), kitchenware (refrigerators, air-conditioners, stoves ......), furniture, ventilation, refrigeration, purification, doors, Decoration, lift and other related metal forming fields.

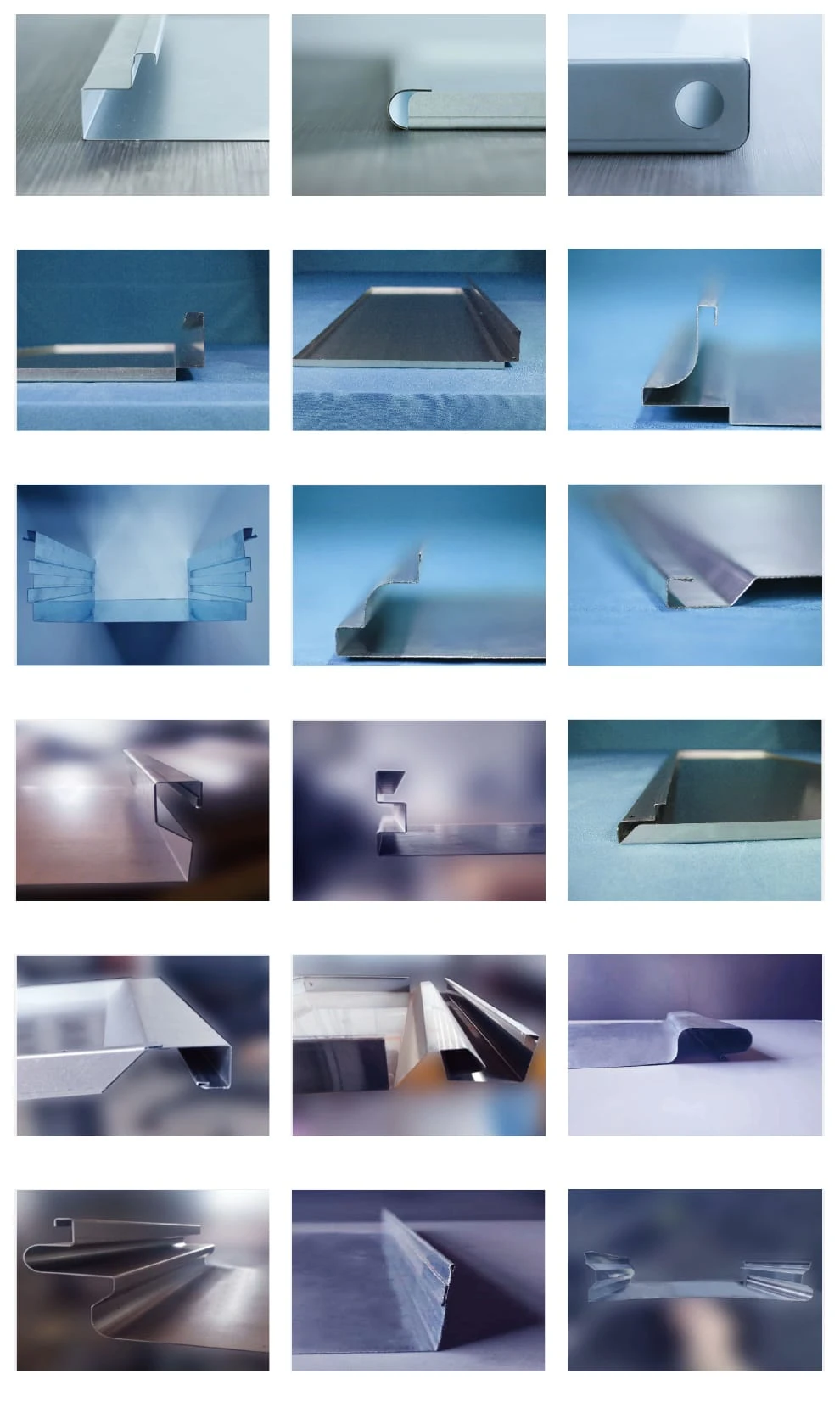

Bending effect

Actual bending shape display