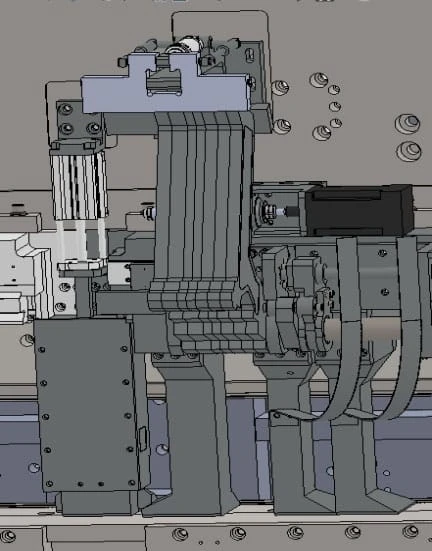

This equipment has the domestic independent intellectual property rights of fully automatic knife changing flexible bending centre, which changes the traditional manual knife changing process and realizes the automation and intelligence of industrial production.

This equipment has the domestic independent intellectual property rights of fully automatic knife changing flexible bending centre, which changes the traditional manual knife changing process and realizes the automation and intelligence of industrial production. Three positioning methods adapt to more plates, achieving high precision and high efficiency production method. The unique fully automatic knife splicing system in China has led the development of fully automatic flexible bending centre in China to take a key step forward.

|

|

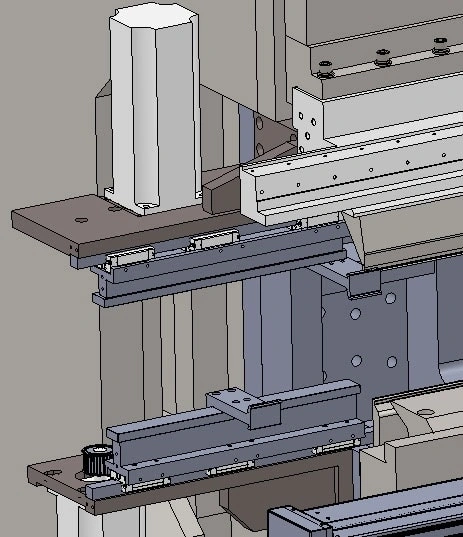

| Shim knife | Auxiliary Bending Knife |

Flexible bending centre focuses on solving all kinds of complex sheet metal and bending problems in metal forming. Through the multi-axis concurrent linkage, automatically complete the sheet metal work, from a technical point of view to solve the dependence on moulds and manpower, effectively improve production efficiency and reduce production costs.

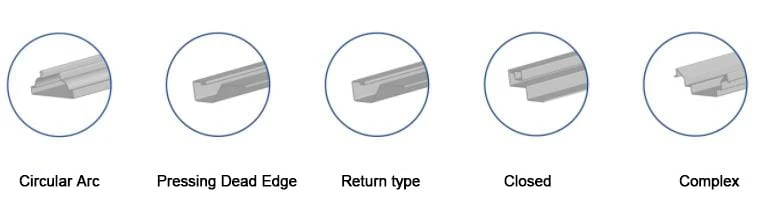

It is easy to realise sheet metal bending needs of arc, dead edge, return type, closed type and other complex types.

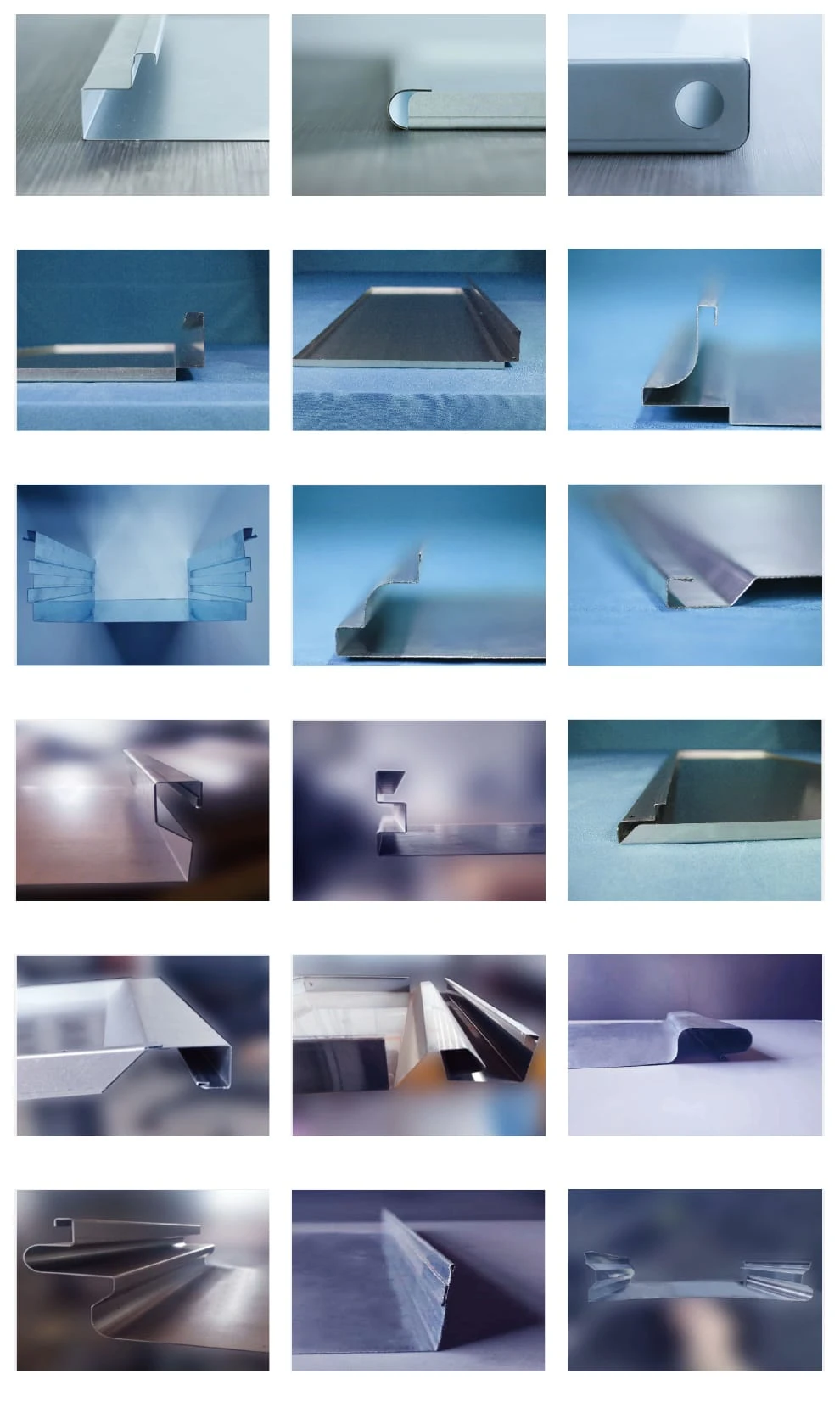

Flexible bending centre can be widely used in the field of steel cabinet shells (filing cabinets, tool cabinets, outer shrouds, electrical cabinets, communication cabinets, gas cabinets, water meter cabinets ......), kitchenware (refrigerators, air-conditioners, stoves ......), furniture, ventilation, refrigeration, purification, doors, Decoration, lift and other related metal forming fields.

Bending effect

Actual bending shape display

| AT-QS2500 full 3WD | |||

|---|---|---|---|

| No. | Name | Unit | Parameter |

| 1 | Feeding structure | / | Pressure arm type |

| 2 | Maximum bending length | mm | 2500*1250 |

| 3 | Maximum bending height | mm | 170 |

| 4 | Minimum bending height | mm | 5 According to the thickness of the board |

| 5 | Minimum internal moulding dimensions on all sides | mm | 370*310 |

| 6 | Minimum internal moulding size for both sides | mm | 310 |

| 7 | Minimum arc radius | mm | 1.2 |

| 8 | Minimum continuous bending speed | S | 0.2 |

| 9 | Bending angle | angle | 0°~180° |

| 10 | Controlled Axes | m/min | Multiaxis |

| 11 | Maximum feeding speed | mm | 120 |

| 12 | Equipment size | mm | 6500*3600*2950 |

| 13 | Total power | KW | 130 |

| 14 | Average power | KW | 6.5 |

| 15 | Workbench structure | Stainless steel workbench | |

| 16 | Speed adjustment | Standard configuration | |

| 17 | Advanced Instructions | Standard configuration | |

| 18 | Arc command | Standard configuration | |

| 19 | Flattening command | Standard configuration | |

| 20 | Loading robot interface | Standard configuration | |

| 21 | Automatic arrangement of press knives | Standard configuration | |

| 22 | Shim knife system | Standard configuration | |

| 23 | Local folding knife system | Standard configuration | |

| 24 | X1 positioning Y movement | Standard configuration | |

| 25 | Automatic lifting of loading and unloading doors | Standard configuration | |