The company's technology research and development department after technical research, in order to meet the customer's processing needs of a variety of plates, on the basis of the thin plate to increase the thick plate bending, developed a thin and thick integrated AT-HS series of thick and thin integrated flexible bending centre.

The company's technology research and development department after technical research, in order to meet the customer's processing needs of a variety of plates, on the basis of the thin plate to increase the thick plate bending, developed a thin and thick integrated AT-HS series of thick and thin integrated flexible bending centre.A

Flexible bending centre focuses on solving all kinds of complex sheet metal and bending problems in metal forming. Through the multi-axis concurrent linkage, automatically complete the sheet metal work, from a technical point of view to solve the dependence on moulds and manpower, effectively improve production efficiency and reduce production costs.

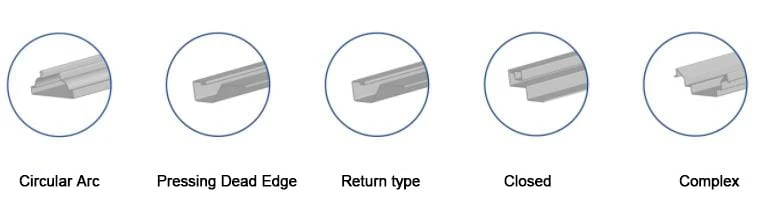

It is easy to realise sheet metal bending needs of arc, dead edge, return type, closed type and other complex types.

Flexible bending centre can be widely used in the field of steel cabinet shells (filing cabinets, tool cabinets, outer shrouds, electrical cabinets, communication cabinets, gas cabinets, water meter cabinets ......), kitchenware (refrigerators, air-conditioners, stoves ......), furniture, ventilation, refrigeration, purification, doors, Decoration, lift and other related metal forming fields.

Bending effect

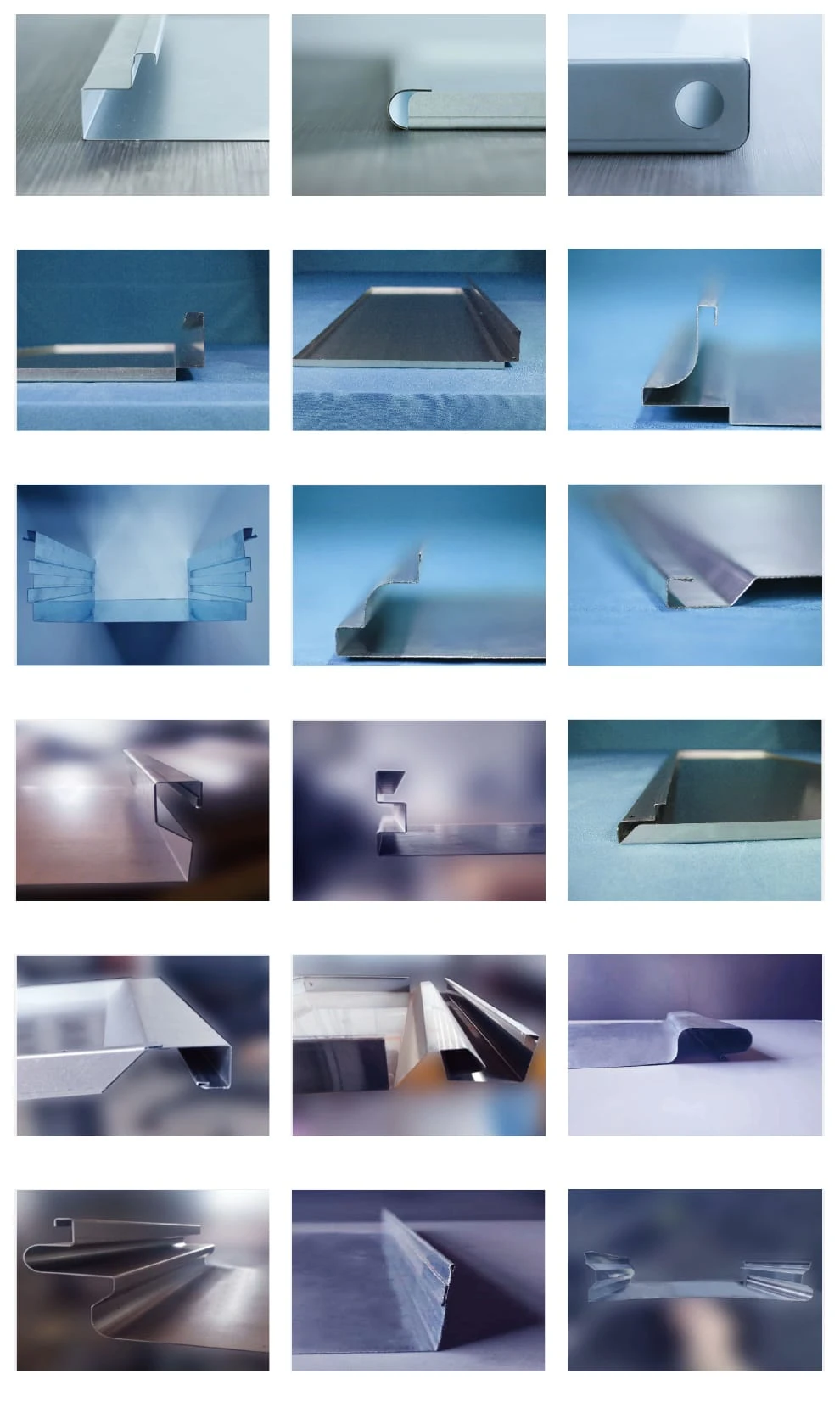

Actual bending shape display

| AT-HS2000-3 | ||

|---|---|---|

| No. | Name | Parameter |

| 1 | Feeding structure | Pressure arm type |

| 2 | Workbench structure | Brush and universal ball |

| 3 | Minimum precision of the system | 0.01mm |

| 4 | Fastest bending speed | 0.2 seconds per blade |

| 5 | Maximum feeding speed | 120m/min |

| 6 | Maximum bending size | 2000mm in length and 1250mm in width |

| 7 | Maximum bending height | 170mm/240mm/280mm (opposite side) |

| 8 | Minimum bending height | 4mm (based on the thickness of the board) |

| 9 | Minimum arc radius | 2mm (based on the thickness of the board) |

| 10 | Rated voltage | 380V |

| 11 | Total power of motor | 93KW |

| 12 | Average operating power | 9.5KW |

| 13 | Noise | About 55 decibels |

| 14 | External dimensions | 5800*3170*2500mm |

| 15 | User operating environment | Windows system |

| 16 | Maximum bending thickness | 304 stainless steel 1.5mm / carbon steel plate 2.0mm / aluminium plate 3.5mm |

| 17 | Minimum material thickness | 0.3mm |

| 18 | Minimum internal dimensions for quadrilateral forming | 160 * 280mm (customizable) |

| 19 | Minimum internal dimensions for double-sided forming | 160mm (customizable) |

| 20 | Bending angle | -90 °~90 ° (>1.5mm) 0 °~180 ° (≤ 1.5mm) (carbon steel) |

| 21 | Number of axes | Customized |