Strong stability. The bending speed is only 0.6 seconds per cut. One-time moulding of workpiece. Full servo control, low energy consumption.

Strong stability.

The bending speed is only 0.6 seconds per cut.

One-time moulding of workpiece.

Full servo control, low energy consumption.

Simple maintenance, low cost.

Foolproof operation, low personnel requirements.

10-axis linkage control, high degree of automation.

Fully automatic loading and unloading, unmanned operation.

Integrated electrical design, easy to operate.

Offset load visualisation design, to ensure the service life of the equipment.

Fully open system port.

Simple and clear system interface, easy to learn.

Wide range of bending materials (carbon steel, 304 stainless steel, 201 stainless steel, aluminium plate, laminated plate, etc.).

Various accurate positioning methods to ensure the bending accuracy of the plate.

Flexible bending centre focuses on solving all kinds of complex sheet metal and bending problems in metal forming. Through the multi-axis concurrent linkage, automatically complete the sheet metal work, from a technical point of view to solve the dependence on moulds and manpower, effectively improve production efficiency and reduce production costs.

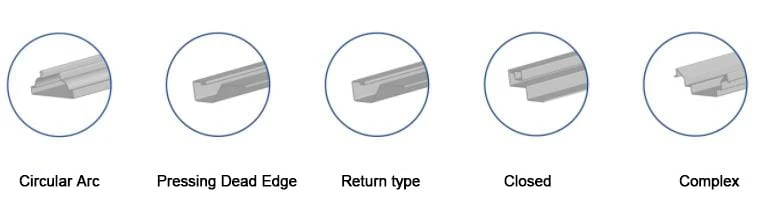

It is easy to realise sheet metal bending needs of arc, dead edge, return type, closed type and other complex types.

Flexible bending centre can be widely used in the field of steel cabinet shells (filing cabinets, tool cabinets, outer shrouds, electrical cabinets, communication cabinets, gas cabinets, water meter cabinets ......), kitchenware (refrigerators, air-conditioners, stoves ......), furniture, ventilation, refrigeration, purification, doors, Decoration, lift and other related metal forming fields.

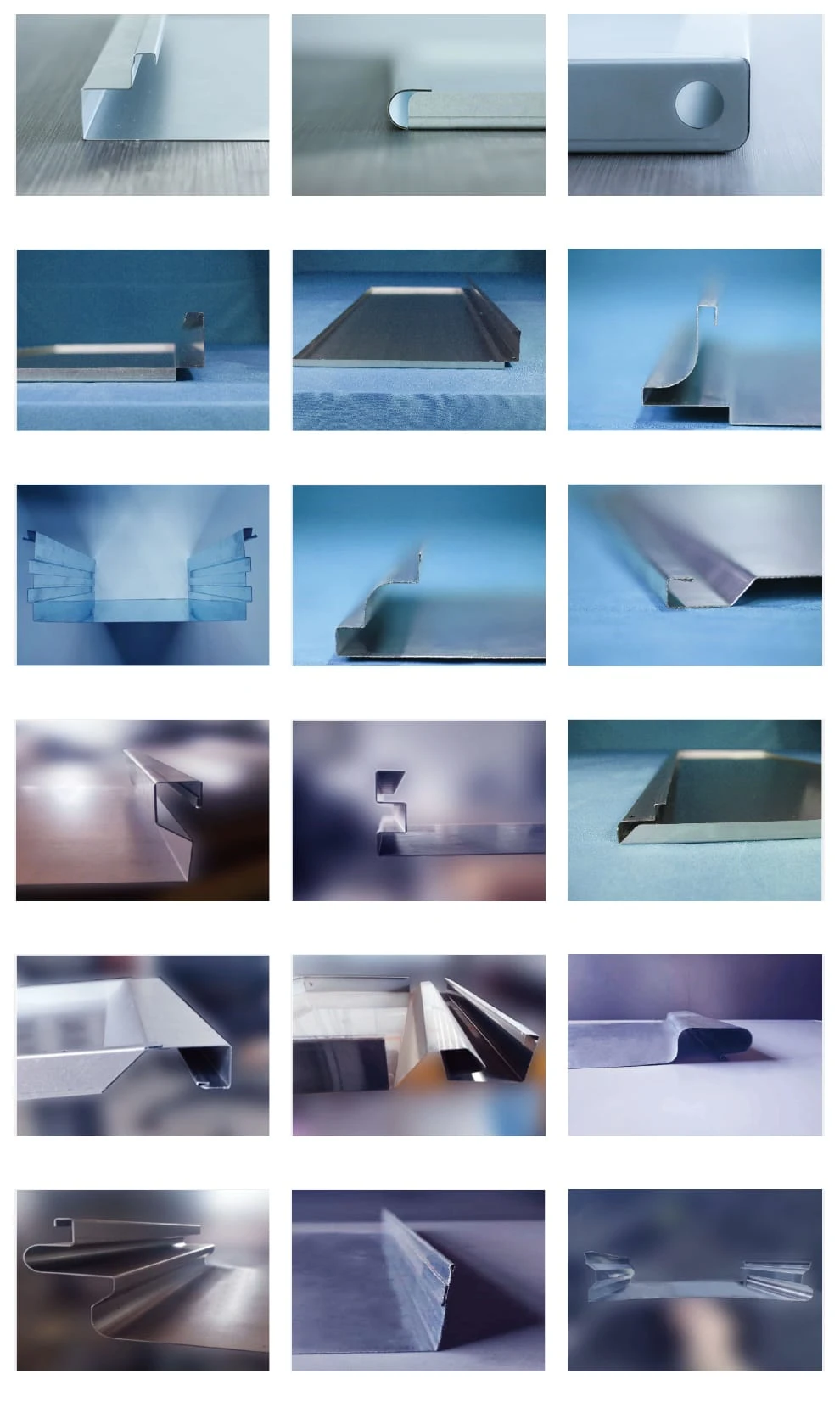

Bending effect

Actual bending shape display

Wide range of bending materials (carbon steel, 304 stainless steel, 201 stainless steel, aluminium, laminate, etc.).